Pest Control Vehicle Inspection Template (+Free PDF Download)

Pest control vehicles function as mobile offices for technicians.

Regular vehicle inspections keep your fleet reliable, ensuring techs arrive at jobs on time and complete tasks efficiently. They also prolong vehicle lifespan and avoid costly breakdowns and repairs, which eat into your profits.

Tracking vehicle maintenance, repairs, and regulatory requirements can be challenging with multiple pest control trucks or vans. A pest control truck inspection checklist streamlines the process and proactively identifies potential issues.

Download this printable vehicle inspection checklist template and follow these tips to optimize your fleet inspection, maintenance, and reporting.

Download the template

Key Areas to Inspect on a Pest Control Vehicle

A vehicle inspection form helps techs complete a thorough inspection, including the exterior, interior, mechanical, and safety equipment.

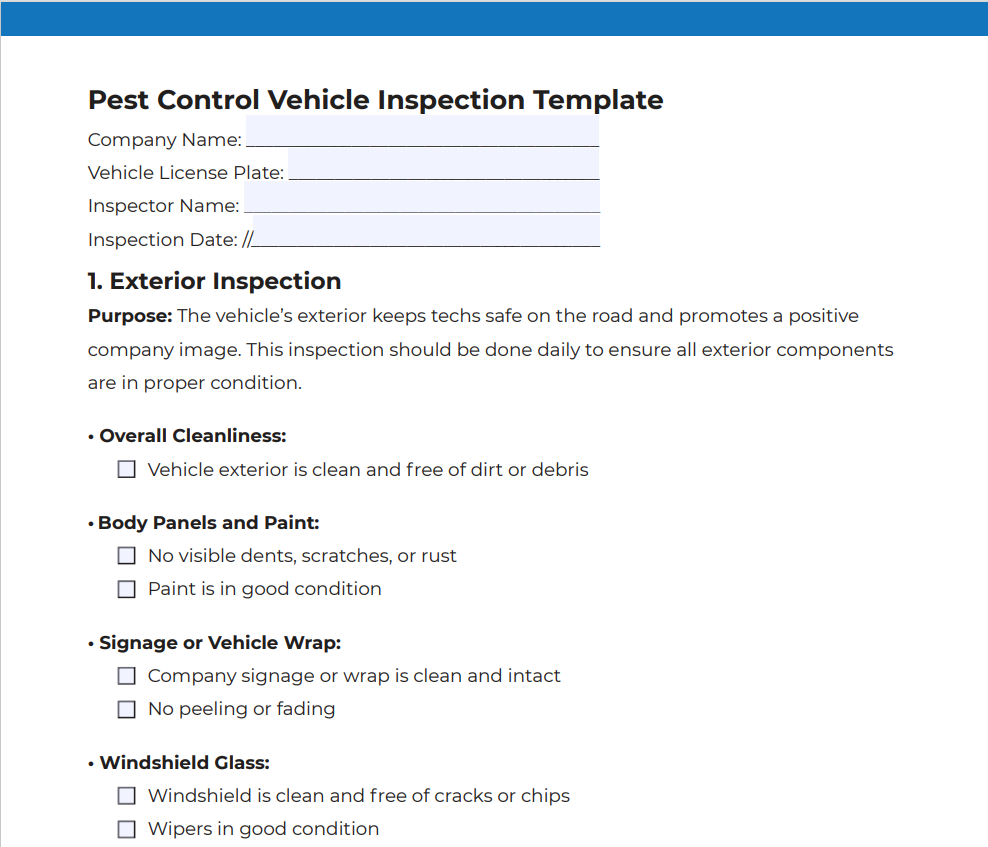

Exterior Inspection

The vehicle’s exterior keeps techs safe on the road and promotes a positive company image. An exterior inspection includes:

Overall cleanliness

Body panels and paint

Signage or vehicle wrap

Windshield glass

Lights and turn signals

Fuel leakage

To complete a walk-around inspection, start from the front or one side of the pest control vehicle and carefully inspect all exterior components.

Interior Inspection

An interior inspection evaluates a vehicle’s seating, controls, and storage areas. A careful interior inspection should include an examination of the following:

Overall cleanliness

Seatbelts

Seat covers

Windshield wipers

Interior lights

HVAC system controls

Storage compartments and fasteners

From a safety standpoint, ensure items in the back of the truck or a van’s cargo area don’t block the rearview mirror’s view. Storage compartments and containers should adequately hold pest control tools and equipment, such as sprayers, hoses, baits, and traps.

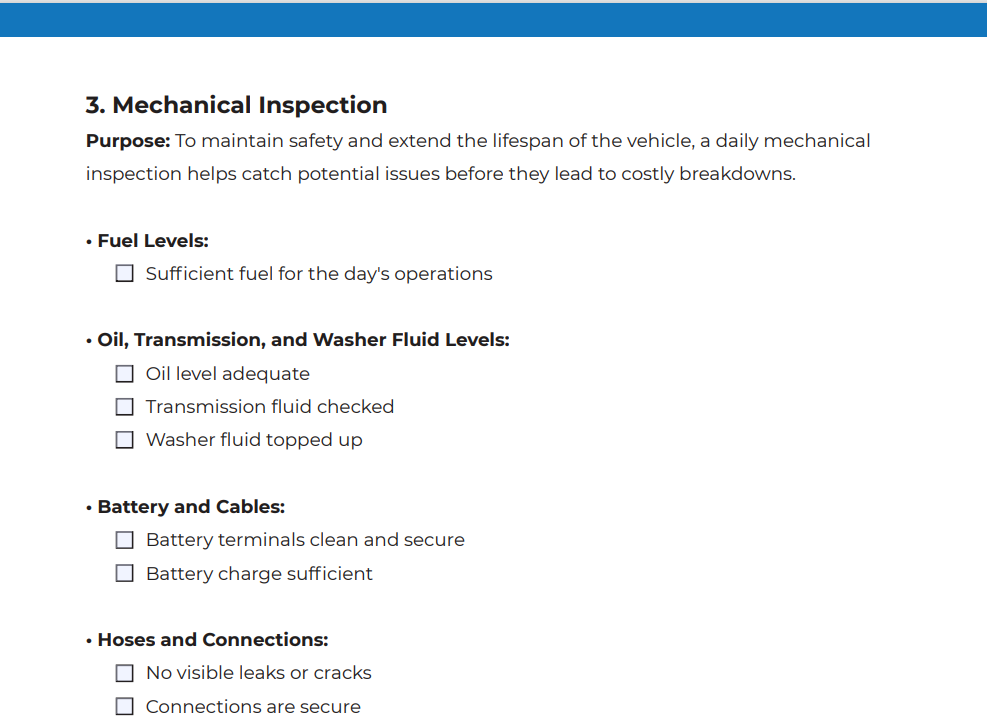

Mechanical Inspection

A mechanical inspection is one of the most important elements of a vehicle inspection report. It assesses automotive function for safety and long-term maintenance. A mechanical inspection includes:

Fuel levels

Oil, transmission, and washer fluid levels

Battery and cables

Hoses and connections

Brakes

Tire treads and pressure

Regular maintenance reduces big-ticket repairs and catches problems before techs get stuck on the side of the road. This includes regular oil and filter changes, air filter cleaning or replacement, suspension checks, and tire rotation.

Safety Equipment

A safety inspection reviews necessary safety equipment for the job or an emergency. A safety equipment inspection checks:

Fire extinguishers

First aid kit

Flashlights, headlamps, and batteries

Jumper cables

Reflective triangles

Wheel chocks

PPE includes protective suits, respirators, goggles, gloves, boot covers, safety harnesses, and pesticide spill kits.

A well-organized truck or van fitted with latched containers and proper fasteners eliminates clutter, tripping hazards, and chemical spills. Equipment stored on a roof rack or in the back of a truck bed needs ratchet straps to stay secure.

Monitor tech driving safety with ServiceTitan Fleet Pro, which integrates with FieldRoutes pest control software. The software alerts pest control companies about route changes, risky driving, and problematic driving behavior.

How Often Should Vehicle Inspections Be Conducted?

Establish an inspection process to include vehicle inspections in your workflow.

Techs should conduct daily inspections before using the vehicle. You don’t want your techs driving a truck with malfunctioning headlights, faulty turn signals, or unfastened containers containing pesticides. Pre-trip inspections also ensure vehicles contain the proper equipment and materials for the jobs each day.

Consider implementing in-depth inspections once a month, bi-monthly, or quarterly. It’s not practical to perform a comprehensive inspection every day, but checking mechanical components regularly identifies potential problems before they need significant repairs.

Generally, professional mechanics should examine pest control vehicles once or twice a year, depending on your in-house vehicle maintenance expertise. Set maintenance schedule reminders based on a timeframe and mileage so vehicle inspections don’t get lost in the daily shuffle.

How to Effectively Communicate Inspection Findings

Optimal vehicle performance relies on the communication of inspection findings.

Techs should promptly report vehicle inspection issues to a supervisor. Unlike manual methods such as pen and paper or carbonless forms, a digital pest control inspection report streamlines the inspection process and accelerates communication.

Best practice inspection methods include:

Inspection report templates: Templates help pest control businesses customize inspections without creating a list from scratch. They deliver a professional look and include essential inspection items.

Digital inspection checklists: Digital checklists help techs efficiently perform inspections before leaving the parking lot. They enable supervisors to see if techs completed all items, if there are any issues, and accompanying photos.

Maintenance notifications: Use FieldRoutes to create internal notifications and set triggers for scheduling.

Mobile app: A pest control mobile app enhances communication between managers and techs. It sends instant updates and enables techs to input notes from the field.

Establish a process that’s best for your business to keep your fleet in top shape.

Regulations Regarding Pest Control Vehicles

Federal regulations set rules for storing, labeling, and transporting hazardous chemicals, including certain pesticides. Check federal and state laws to ensure your pest management company remains compliant.

Agencies with regulations or standards relating to pesticide safety, storage, and transport include:

The Environmental Protection Agency: The EPA regulates pesticide storage through instructions on pesticide labels. States regulating pesticide storage in small containers include Maine, New Hampshire, North Carolina, and Washington. Follow EPA recommendations for secondary containers using sticker labels with key pesticide data.

Department of Transportation: The DOT sets rules for transporting hazardous materials, including certain pesticides. Drivers in a vehicle with a pesticide that requires vehicle placarding must possess a Class “C” commercial driver’s license.

Occupational Safety and Health Administration: OSHA guidelines and regulations protect pest control applicators and businesses.

Regarding pest control vehicles, the EPA also sets emission standards for vehicles and trucks.

Regular inspections ensure your pest control business maintains compliance with labeling, storage, and transportation regulations.

Make the Vehicle Inspection Process Easier With the Right Technology

A pest control vehicle inspection template simplifies the inspection process but performs a limited role unless it is connected to the rest of your business operations.

FieldRoutes Operations Suite streamlines scheduling, routing, collections, and reporting, empowering pest control businesses to improve performance and profit. The all-in-one software simplifies work order management, including pest control-specific tools for termite property inspections, warranties, and renewals.

Whether you’re starting a pest control business or seeking to accelerate growth, FieldRoutes helps you simplify tasks, save time, and grow revenue.

Schedule a demo to see FieldRoutes features in action.